Years of Expertise

Your Industrial Knife Partner, Solution To Your Industrial Needs.

About Goldken Sdn. Bhd.

Established in 1993 as Goldken Trading and later rebranded as Goldken Sdn Bhd, we are a leading specialist in industrial knives and precision grinding services. With over 32 years of industry experience, we serve a wide range of sectors by delivering high-performance cutting solutions tailored to modern industrial demands.

Our advanced workshop utilizes state-of-the-art technology to produce Standard-Finish, Super-Finish, and Mirror-Finish blades, along with a comprehensive range of replacement knives and cutting accessories. Safety remains a core focus of our operations, supported by safety accessories, inspection services, and free blade disposal.

Driven by a commitment to Total Customer Satisfaction, we go beyond products by providing technical consultation and cutting tool life optimization—ensuring reliable performance and long-term value for our customers.

Experience the Goldken difference—where precision meets reliability.

We deliver precision sharpening solutions that ensure clean, consistent, and efficient cutting performance across:

- Paper & Printing Industry

- Non-Woven Industry

- Steel & Metal Processing Solution

- Semiconductor Industry Solutions

- Safety & Handling

Supporting Industries Since 1993

Paper & Printing Industry Solutions

1993 — Our first industry served and the foundation of our precision expertise.

Goldken Sdn Bhd began its journey in the paper and printing industry, one of our core sectors. This industry faces challenges such as frayed edges, machine vibration, and costly downtime from dull or misaligned knives.

Our Expertise

- Precision regrinding to restore optimal blade geometry

- Maintaining exact bevel angles and edge sharpness

- Ensuring straightness and flatness for uniform pressure

- Extending knife lifespan and reducing wear on supporting components

- Delivering smoother cuts, less paper dust, and longer intervals between sharpening cycles

Non-Woven Industry Solutions

Mid–1990s — Expanded into non-woven cutting solutions.

Cutting non-woven fabrics presents unique challenges such as fiber fraying, material distortion, static buildup, and knife wear. Goldken Sdn Bhd ensures clean, precise cuts and consistent production quality.

Our Expertise

- Precision-honed edges to prevent fiber tearing or fuzzing

- Optimized bevel angles for specific non-woven densities and bonding methods

- Ultra-smooth polishing to minimize heat and static buildup

- Rigorous concentricity and balance checks for vibration-free cutting

- Fast turnaround to minimize downtime in high-volume operations

Steel & Metal Processing Solutions

Early 2000s — Our first diversification into heavy-duty cutting industries.

Metal cutting faces rapid edge dulling, burr formation, vibration, and heat buildup due to the hardness of materials. Goldken ensures precise, durable, and stable blade performance for high-demand steel and metal operations.

Our Expertise

- Tight-tolerance regrinding for accurate bevels

- Heat-controlled grinding to prevent warping

- Precision balancing for vibration-free cutting

- Smooth finishing to reduce friction

- Longer blade life, cleaner cuts, faster throughput

Wood Processing Industry

Early 2000s — Expanded alongside metal processing applications.

Wood processing demands precise, durable cutting performance across sawing, milling, and panel production. Goldken’s precision grinding services help maintain sharp, balanced blades that deliver cleaner cuts, reduce material waste, extend knife life, and support safe, efficient operations.

- Cleaner, straighter cuts with less sanding required

- Fewer damaged boards or rejected panels

- Extended knife life between sharpenings

- Reduced motor load and lower energy use

- Safer operations with less vibration and kickback

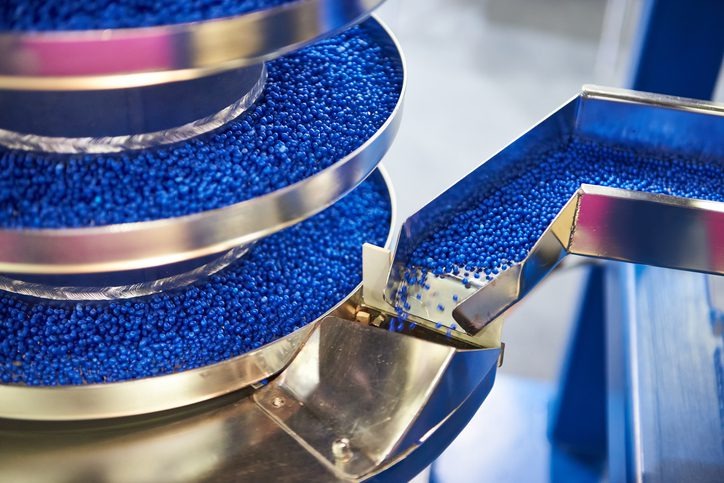

Plastic & Rubber Manufacturing Solutions

2001 — Our first major market diversification.

The plastic and rubber manufacturing industry relies on precision cutting to maintain product quality and production efficiency across a wide range of materials. From rigid plastics to soft elastomers and synthetic rubber, blade geometry and edge quality are essential for achieving clean, consistent cuts throughout the manufacturing process.

Our Expertise

- Cleaner cuts and sharper product finishes

- Reduced product waste and rework

- Improved production line speed and uptime

- Lower energy consumption due to reduced resistance

- Extended knife and machine lifespan

Recycling & Waste Management Solutions

2008 — Second diversification into high-wear cutting environments.

The recycling industry is essential to sustainable waste management, relying on heavy-duty cutting systems to process a wide range of materials efficiently. Industrial knives used in shredding and granulating applications must withstand abrasive, mixed materials under high loads, making blade durability, sharpness, and edge retention critical to reliable plant performance.

Our Expertise

- Increased productivity and material throughput

- Reduced energy use and wear-and-tear on equipment

- Longer knife lifespan, reducing frequency of replacements

- More uniform output sizes for efficient downstream processing

- Safer operation with reduced blade failure risk

Semiconductor Industry Solutions

2012 — Our latest industry sector with over 10 years of experience.

Semiconductor production demands ultra-precise, contamination-free cutting. Key challenges include micro-chipping, particle contamination, blade misalignment, and yield loss from defective cuts. Goldken delivers micron-level grinding accuracy to protect delicate materials like wafers, FPC, insulation films, and thin metals.

Our Expertise

- Micron-precision regrinding for ultra-sharp, symmetric edges

- Burr-free finishing to prevent contamination

- Material-specific grinding for carbide, ceramic, and tool steel blades

- Precision balancing for stable high-RPM cutting

- Higher yield, cleaner cuts, longer blade life, and reduced downtime

QA Reporting (Upon Request) & Technical Support

Inspection Reports

Upon request, we provide clear inspection reports with each batch of blades.

- Blade condition (before & after service)

- Tolerance and specification checks

- Maintenance or replacement recommendations

Ideal for regulated industries requiring traceability and compliance.

Our QC Process

- Incoming: Visual and dimensional inspection

- In-Process: Angle, straightness, and accuracy checks

- Final: Sharpness, dimensions, and finish verification

This process improves consistency and reduces failure risk.

Technical Support

Expertise beyond sharpening

We help customers solve cutting issues, improve performance, and extend blade life.

What We Offer

- Knife application and material consultation

- Tool life and regrinding optimization

- Cutting issue troubleshooting

Support is available on-site or remotely.

Why It Matters

- Experienced technical specialists

- Fast, practical recommendations

- Solutions aligned with production goals

We help reduce downtime, control costs, and improve efficiency.